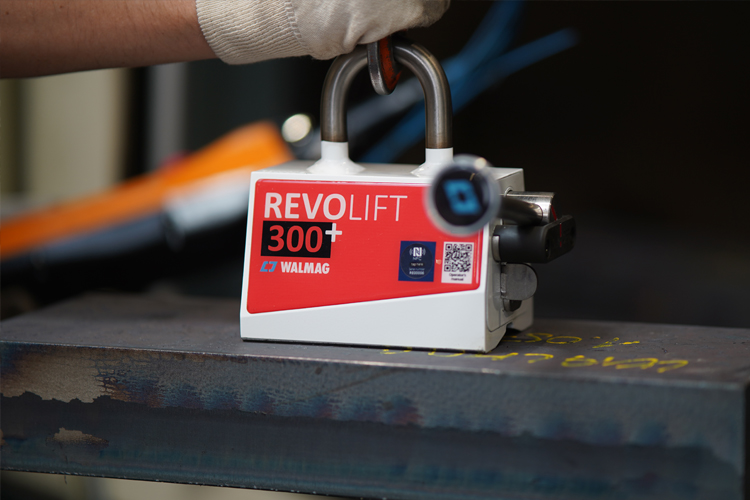

After years of experience with our top quality Neolift permanent lifting magnet. We are introducing the new product from Walmag Magnetics the Revolift – perfect for everyday steel handling. Walmag Magnetics have spent years creating this new concept of the future of permanent lifting magnets.

Please contact us to find out more about this product range.

Magswitch Technology’s first magnetic drill to market, the MagDrill Disruptor 30, is a winner in the fourth annual Pro Tool Innovation Awards.

Magswitch Technology’s first magnetic drill to market, the MagDrill Disruptor 30, is a winner in the fourth annual Pro Tool Innovation Awards.