Description

Fields of application

The vacuum lifter can be optimally used for the following fields of application:

Wood and furniture industry, sheet metal processing, material cutting, Metal Pre-production, coated wood panels, plastic sheets, glass panes

Performance

150 kg to 1000 kg load capacity

4 to 8 suction plates for different materials

Double safety due to second vacuum pump

Increased energy efficiency through automatic power saving

Expandable through additional options

Ergonomic handling due to multi functional handle

Increased productivity through user-centric function

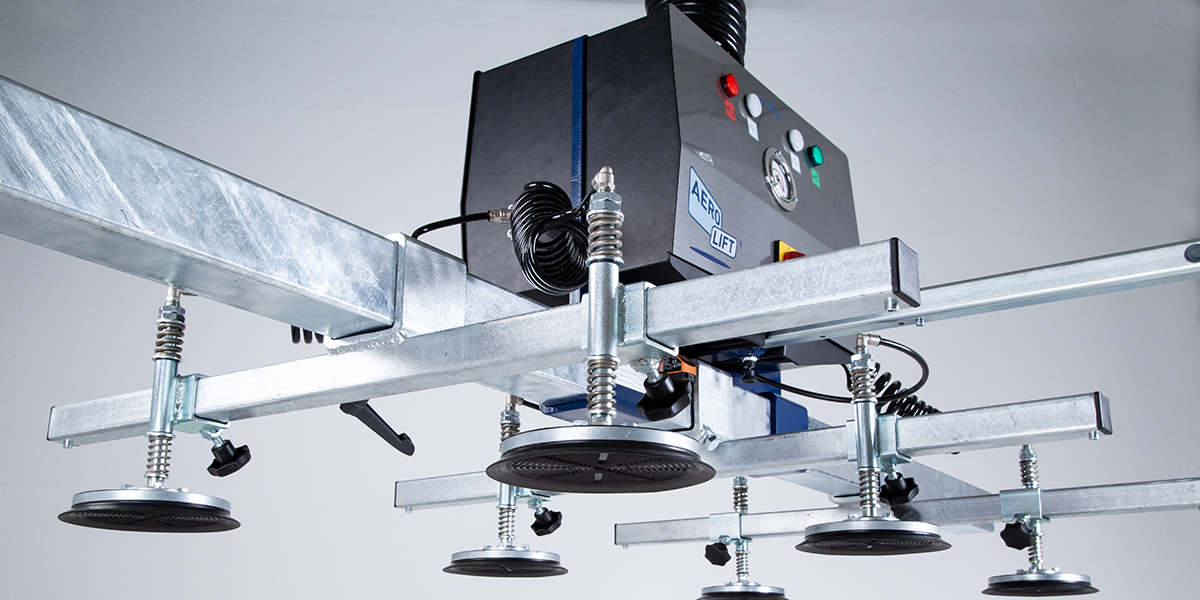

Strengths of the Aero-Advance

Integration of crane control directly on the control panel possible thanks to optional harmonisation between the chain hoist and the device

Real-time display of the vacuum level thanks to LED lights, which provide information about the operational readiness of the system.

Suction and release function via a push button on a modern control panel

Unrivalled versatility of the modular basic system, which can be individually expanded with additional options

Maximum process reliability combined with first-class aesthetics due to its housing made of unbreakable plastic with an aluminium brushed look and hot-dip galvanised steel crossbars

Short set-up times for different transport good dimensions due to suction plates that can be individually locked in place using manual slide valves (already included in the basic package)

Damage-free and gentle transportation thanks to the outstanding-quality full elastomer seals with an extremely long service life

Maximum energy efficiency and therefore low operating costs because of the integrated pump control module, which ensures intelligent regulation of the vacuum generator.

Guaranteed work and operator safety thanks to the generously dimensioned vacuum reservoir with an intelligent warning device

Quick and easy maintenance: The intelligent suction plate concept enables worn suction seals to be replaced in seconds with virtually no tools.

Individualisation with additional options:

Motor-protective circuit-breaker

With the motor-protective circuit-breaker, malfunctions of the vacuum generators are consistently excluded. This additional safety mechanism gives the vacuum lifter a longer service life and reduces the repair effort.

Suction and release via solenoid valve

An electromagnetic valve for the suction and release functions makes manual work much easier for the user. These functions are performed by simply pressing a button on the control panel.

Spiral cable for power and control

The torsion-resistant spiral cable ensures comfortable handling. The spiral design virtually eliminates jamming and twisting, and the crane and vacuum lifter can be controlled conveniently from one location: the multi-function handle.

Supporting feet

The vacuum lifter can be safely parked on the parking feet if required without loading the sensitive suction plates. Thanks to the feet, the device can be stored unused for a longer period of time without negative influences on the traverse and suction cup.

Individually lockable suction plates

Individually lockable suction plates enable more flexible handling of goods of different sizes.

Warning device

Additional warning lights increase safety for users. The addition of red/green LEDs in the housing reliably indicates malfunctions and malfunctions and adds optical signals to the existing warning device.

Spiral cable for power supply

The torsion-resistant spiral cable for the power supply ensures easy handling even for longer lifting distances. Due to the spiral design, the working area is always free of cables and jamming and twisting is almost impossible.

Water separator

As soon as it gets a little more humid in the area of use, the use of a water separator is worthwhile. This reduces moisture in the vacuum circuit, protects sensitive components from moisture and increases the service life of the system.

Support feet with castors

Support feet with castors allow the vacuum lifter to be safely parked when required without loading the sensitive suction plates. Thanks to the castors as supporting feet, the device can be flexibly stored without negative influences on the traverse and suction cup.

Maintenance & UVV inspection

With an annual maintenance and inspection of your vacuum lifter in accordance with the accident prevention regulations (UVV), you achieve increased reliability for man and machine.