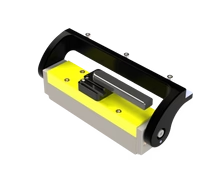

Description

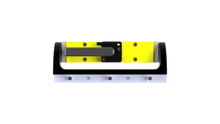

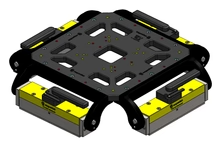

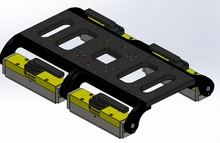

Pairs of MagWings can be anchored flat or pivoted to allow mounting to cylindrical ferromagnetic surfaces. Customers can design their own bases for the MagWing to mount drills, COBOTs, or other tools to make work faster, safer and easier. Included hardware (M8x1.25 screws and two 8mm dowel pins) should be used to attach custom bases to MagWings. Refer to the dimensional drawing below for fastener locations or consult our Applications Team for help with sizing for COBOT applications as we will consider payload, reach, mounting surface and attitude.

Sold as individual units, most applications require two or more MagWings.

Custom mounting plate, bolt and dowel patterns can be incorporated. Contact us for more information

| Material Thickness – mm (in) | 1.5 (.059) | 1.9 (.075) | 2.7 (.106) | 3 (.118) | 3.5 (.138) | 4.76 (.187) | 6.35 (.250) | 9.53 (0.375) | 12.7 (0.500) | 19.05 (0.750) |

| Max Force – N | 1585 | 2109 | 3503 | 3648 | 4058 | 5591 | 8626 | 10241 | 10712 | 11036 |